Process of making Our Hemp Bags

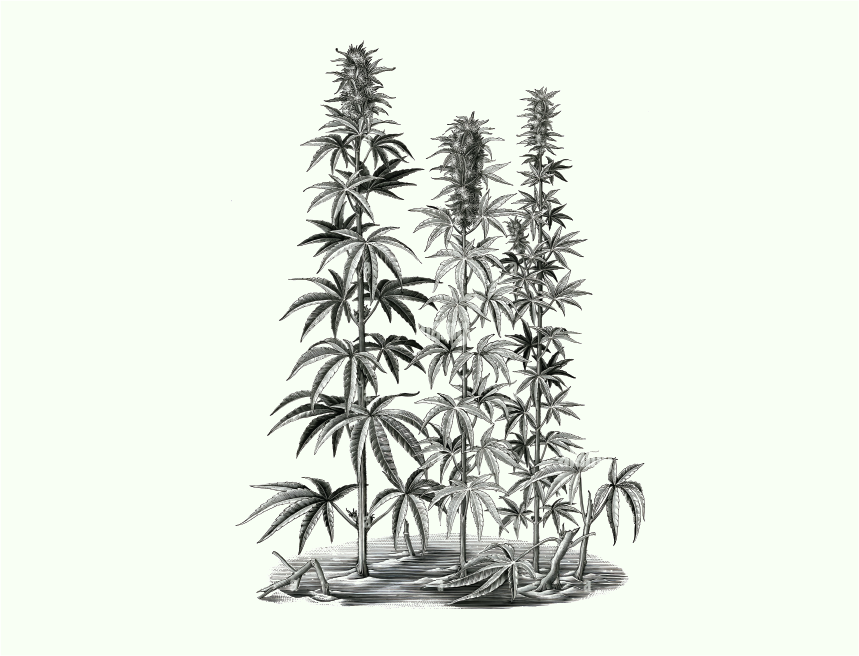

1. Cultivation & Harvesting

Hemp plants are grown for 4–5 months before they are ready for harvest.

The plants are cut close to the ground when they reach maturity.

Only the stalks are used for fiber; the seeds and flowers can be used for other purposes (e.g., food, oil, CBD).

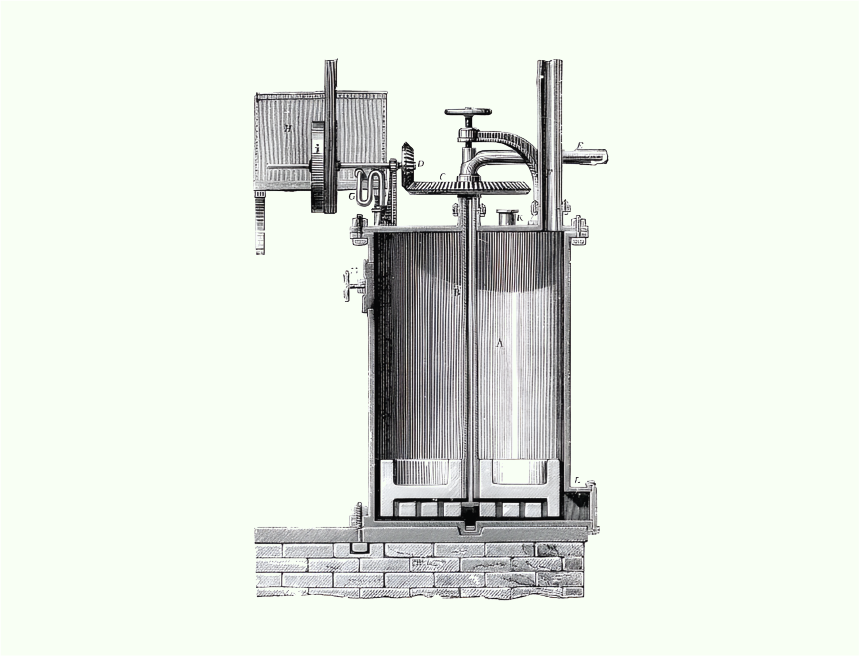

2. Retting (Separating Fiber from Stalks)

The stalks go through a process called retting, which breaks down the plant’s natural pectins (gums) that bind the fibers.

Types of retting:

1. Dew retting: Stalks are left in the field for microbial breakdown (slow process).

2. Water retting: Stalks are soaked in water (common in traditional methods).

3. Chemical retting: Uses alkaline solutions (like NaOH) for faster breakdown.

4. Enzymatic retting: Eco-friendly enzymes break down the pectins.

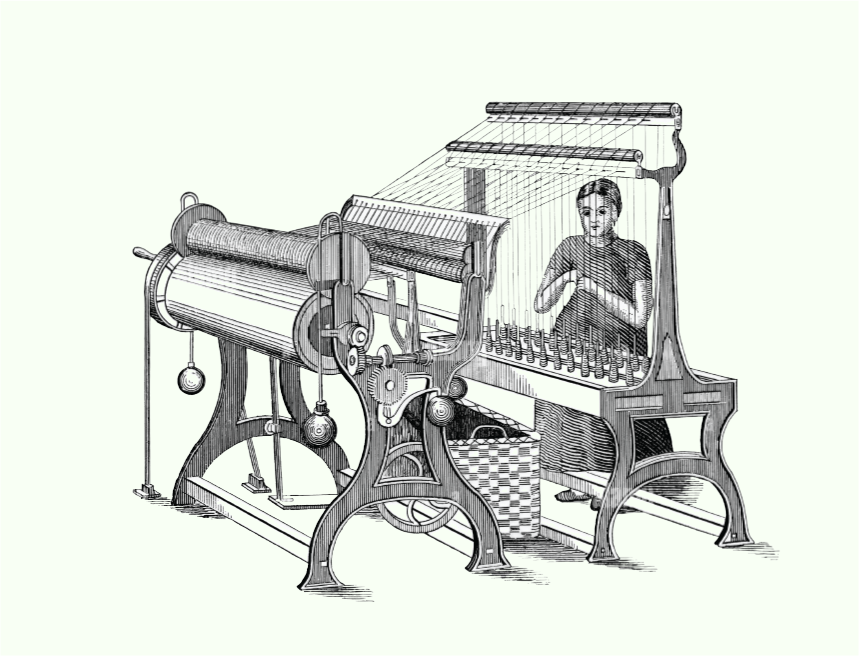

3.Decortication (Fiber Separation)

The dried stalks are crushed and beaten to remove the woody core (hurd) and extract the bast fibers.

Modern machines use rollers and breakers to efficiently separate fiber from the woody part.

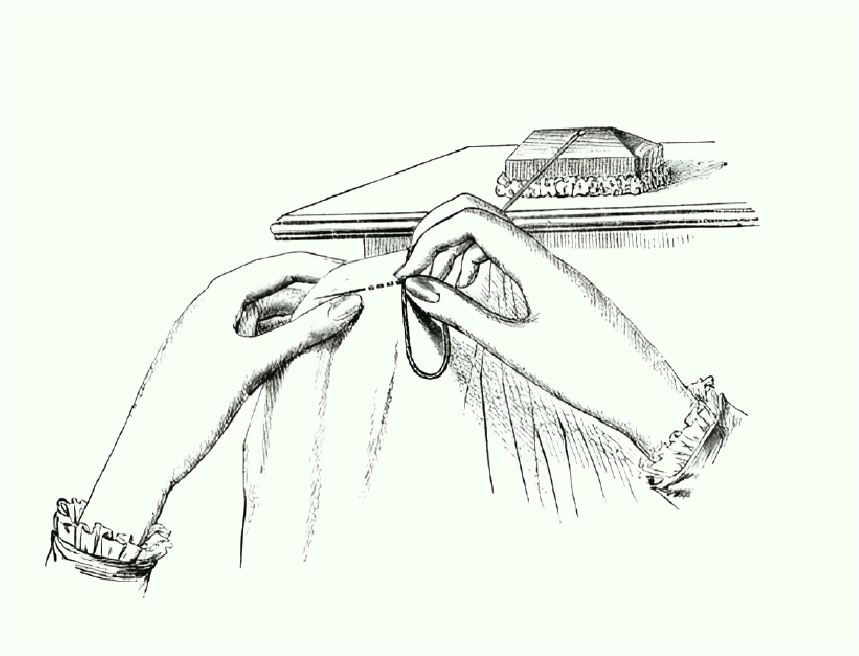

4. Crafting The Final Product

Skilled hands weave these fibers into the durable fabric,

cutting & sewing it into the shape of your future favorite bag.

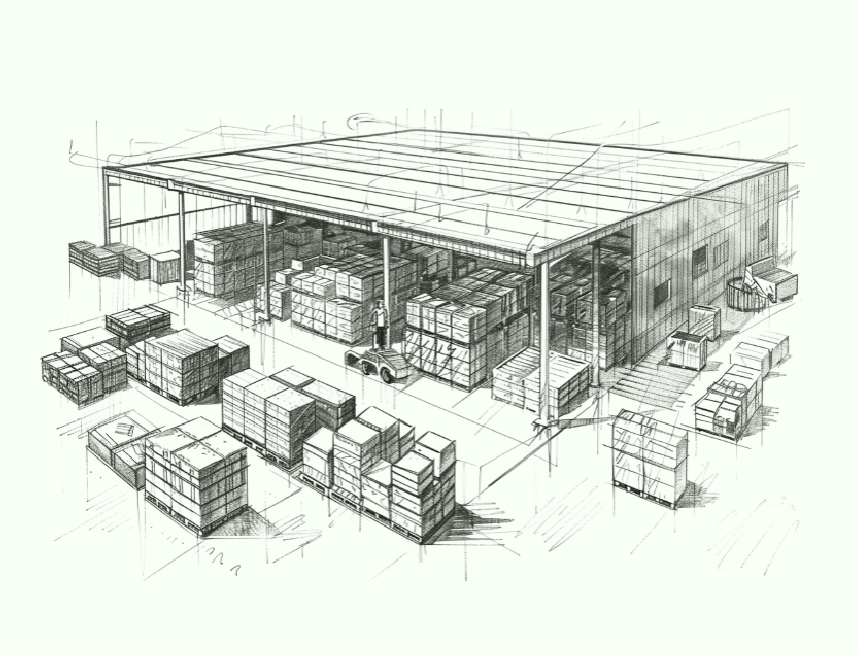

5. Packaging for Shipment

Our bags are lovingly packed with care, ensuring they arrive at your doorstep safe and sound.

6. Delivering The Desired Product

Your journey with us culminates as your new hemp bag

arrives, ready to be your everyday companion.